REAR END REBUILD

When building out the rear suspension, the coil overs were set and cycled; I was able to tack the bump pads, shock mounts and initial(inner-most) limit strap tabs in place as well. With the axle now removed, it was time to fully rebuild it. The rebuild involved welding out the limit strap tabs, plating and boxing in the panhard bar mount(weld washers were added as well), building out the lower shock mounts, gussets on the upper link mounts, in addition to said completion was to rework the upper link gussets. All plating, mounts and tabs were constructed with 4130 Chromoly and double passed.

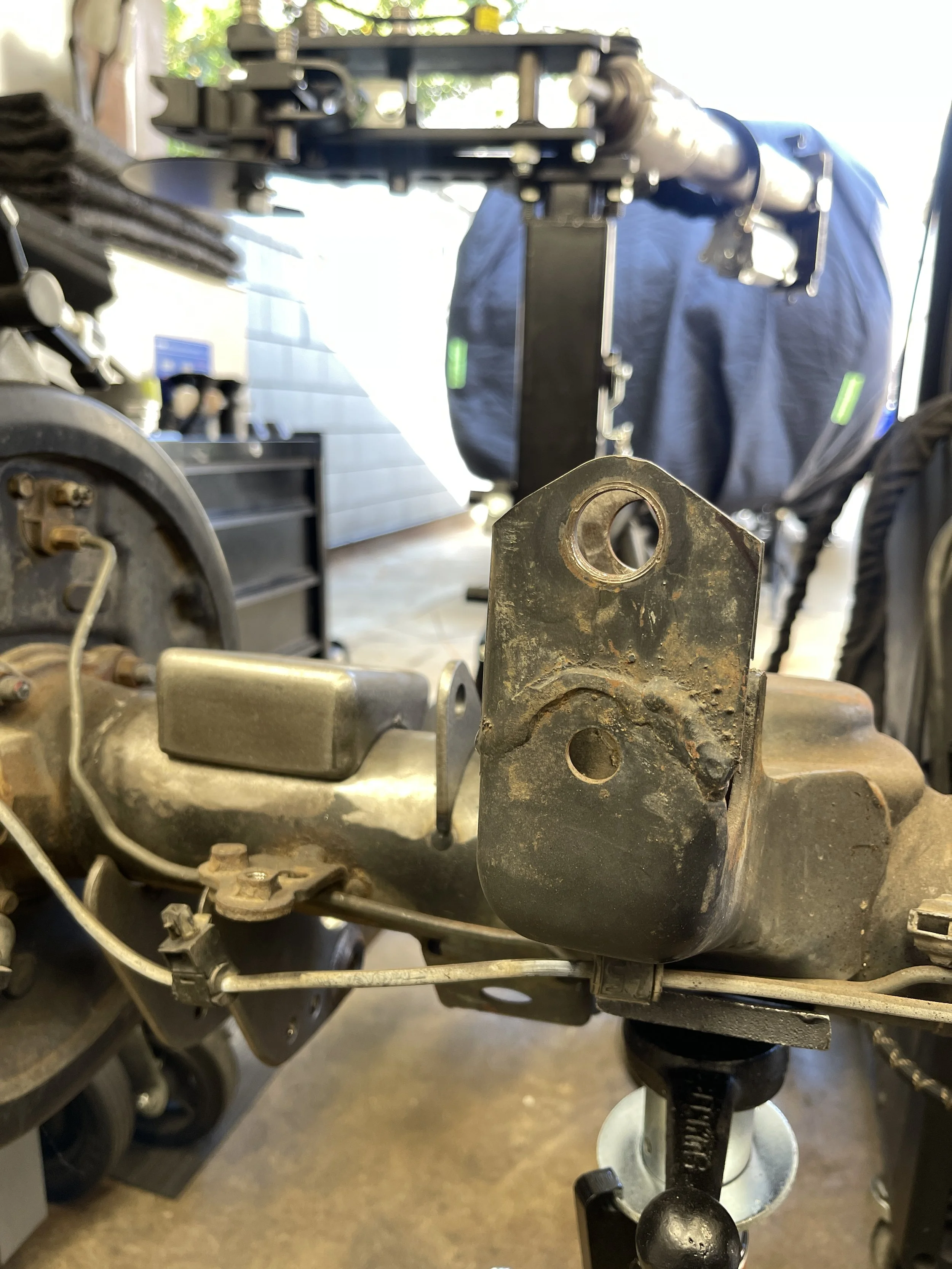

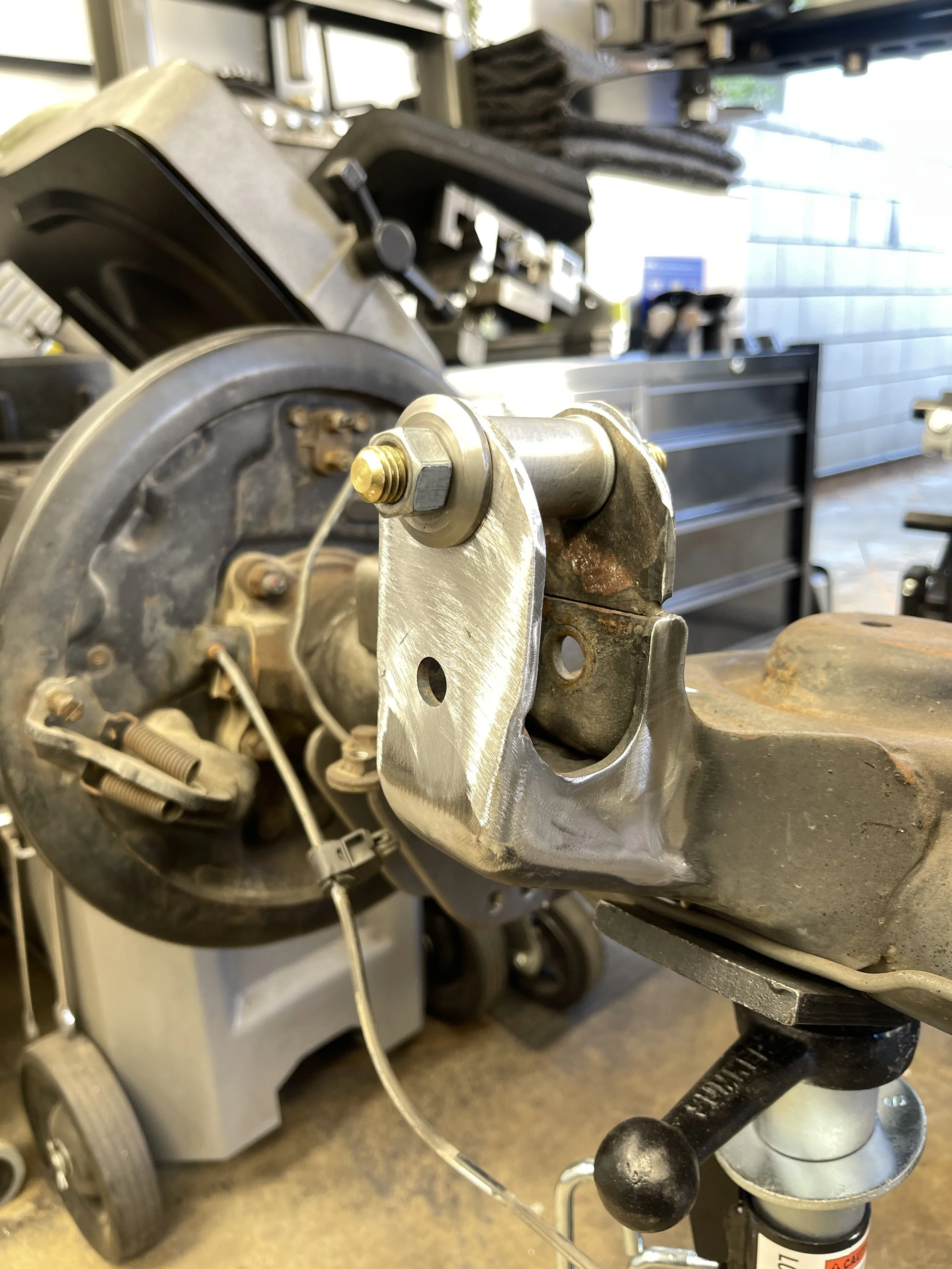

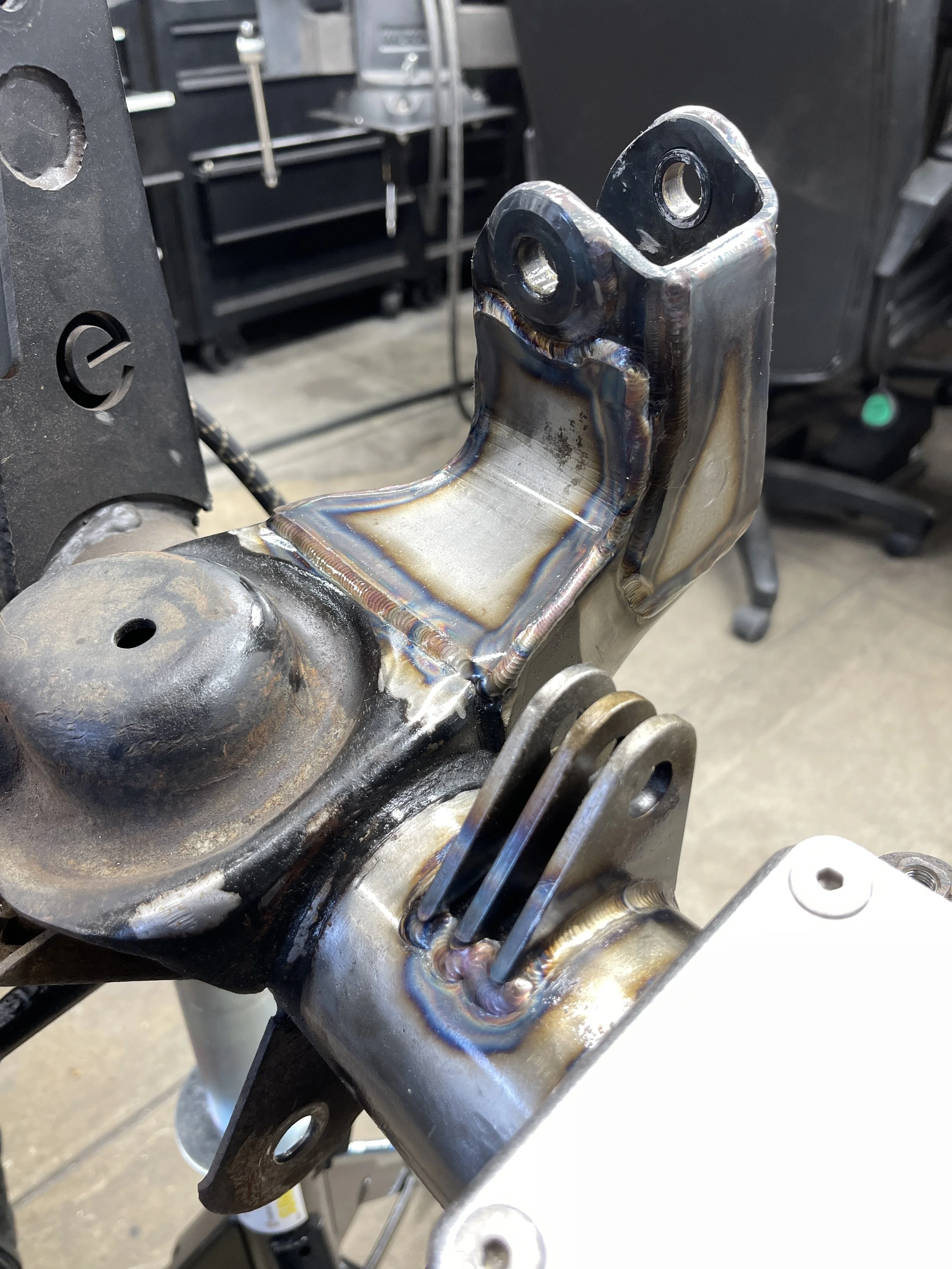

The Eimkeith Panhard Bar relocation mount was previously welded on but didn’t prove to be optimally welded and penetrated throughout. I opted to grind it out, re-weld it and add weld washers as well. Once shaven down and prepped, plating was added to all four sides as well as inside(after the inner seam was welded out).

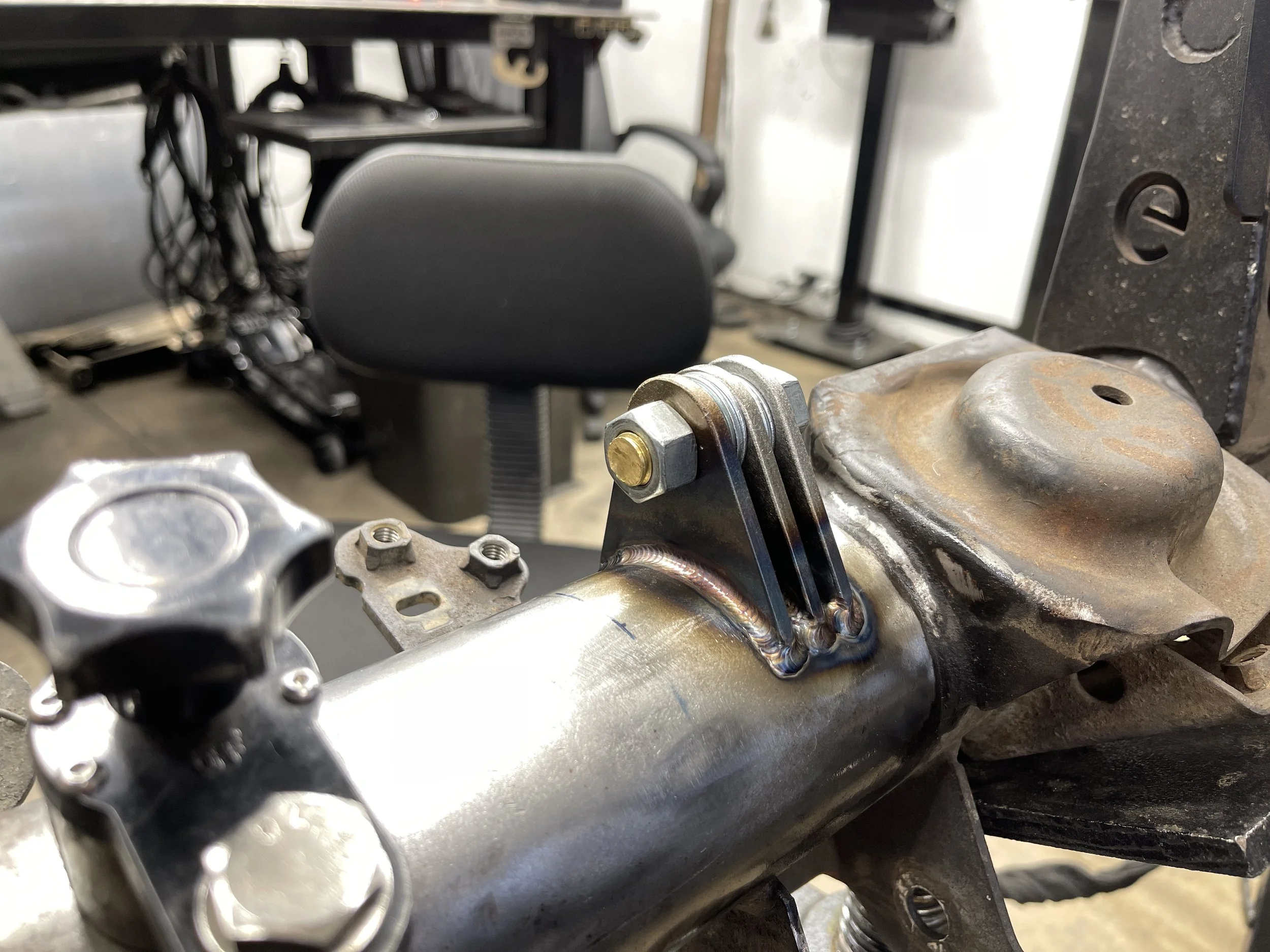

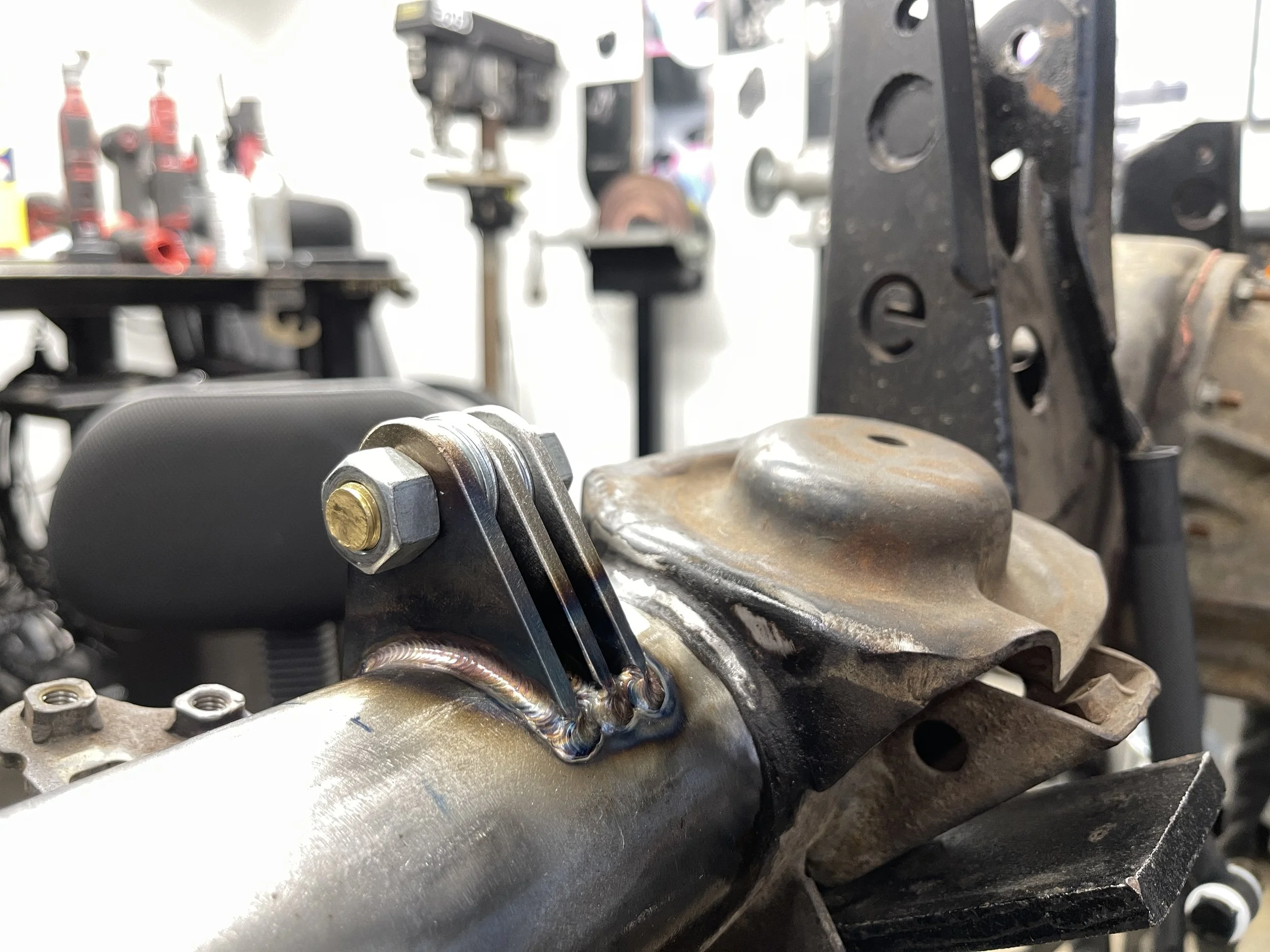

The limit strap tabs were spaced apart to allow for the use of single or dual limit straps per corner. The front arms feature this addition as well.

A full weld out of the bump pads was in order. I opted as well to drill and tap the thick walled strike surface to allow for replaceable pads to be mounted. Fine tuning can be made as well with the thickness of said plate in conjunction with the bump stop mounting on the chassis side.

Here’s a closer look of the panhard bar rework and plating it in. The lower foremost corner was offset downward as well to allow for head of the 1/2 bolt and washer to be mounted in the limit strap tabs.

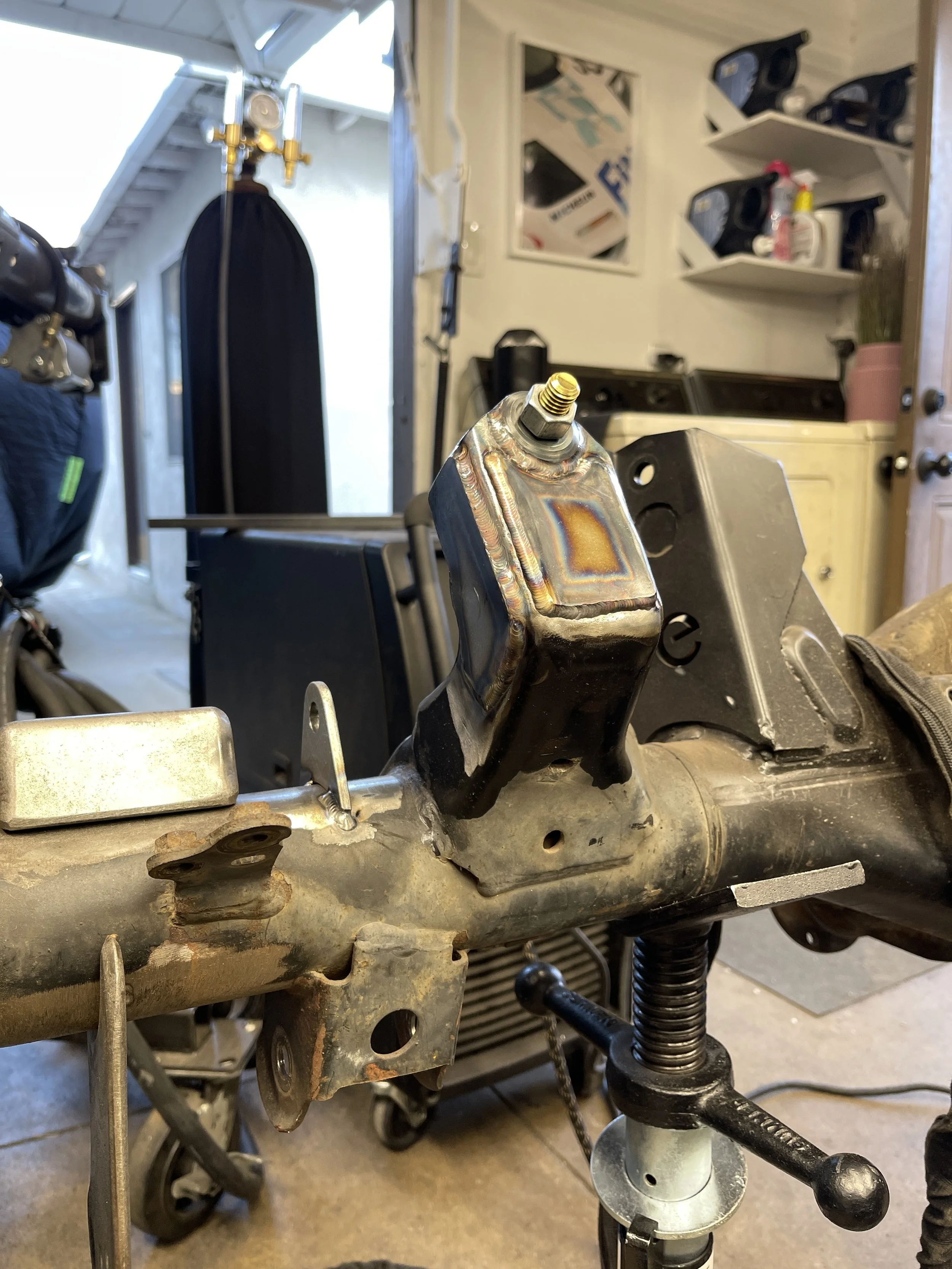

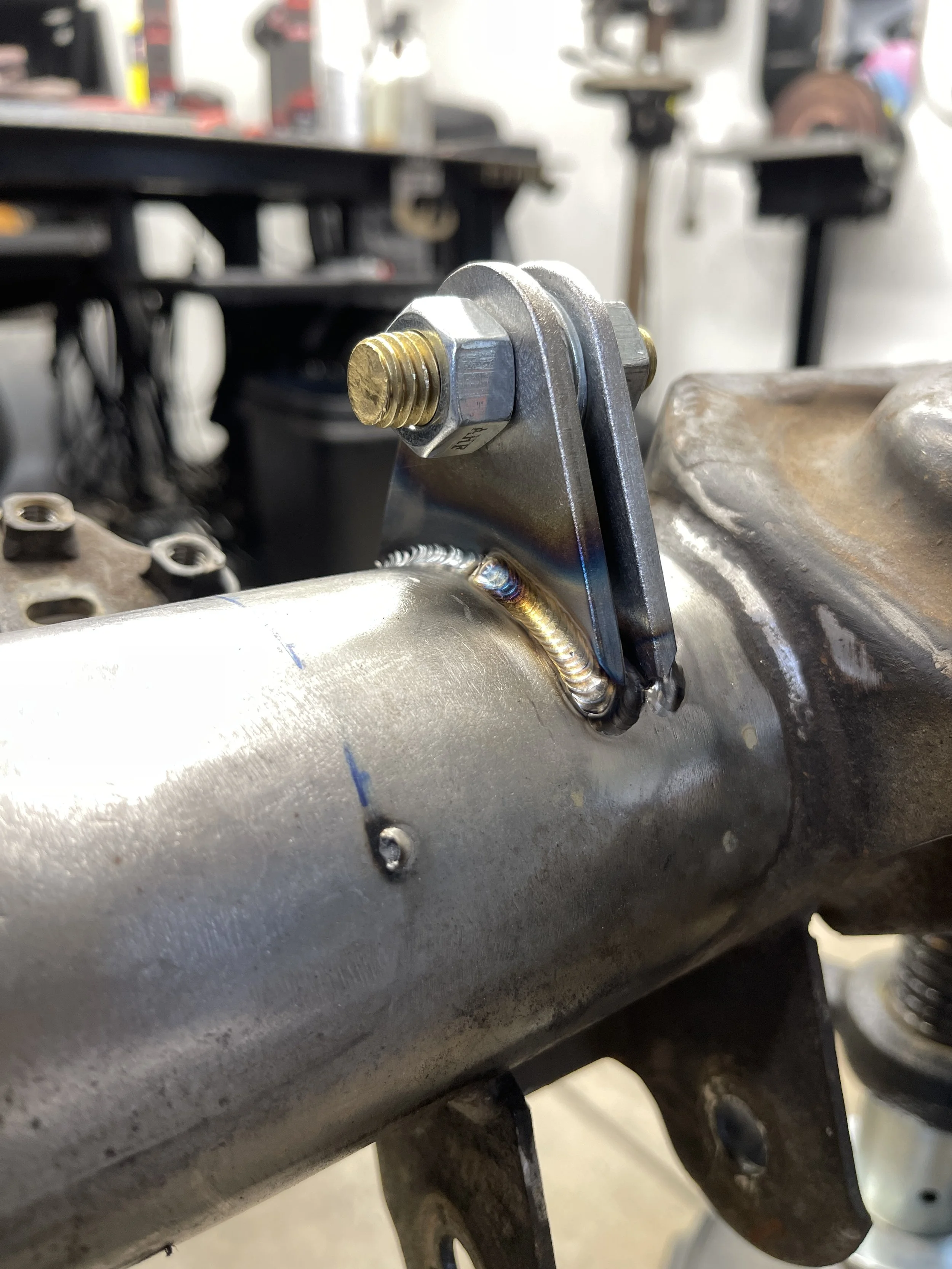

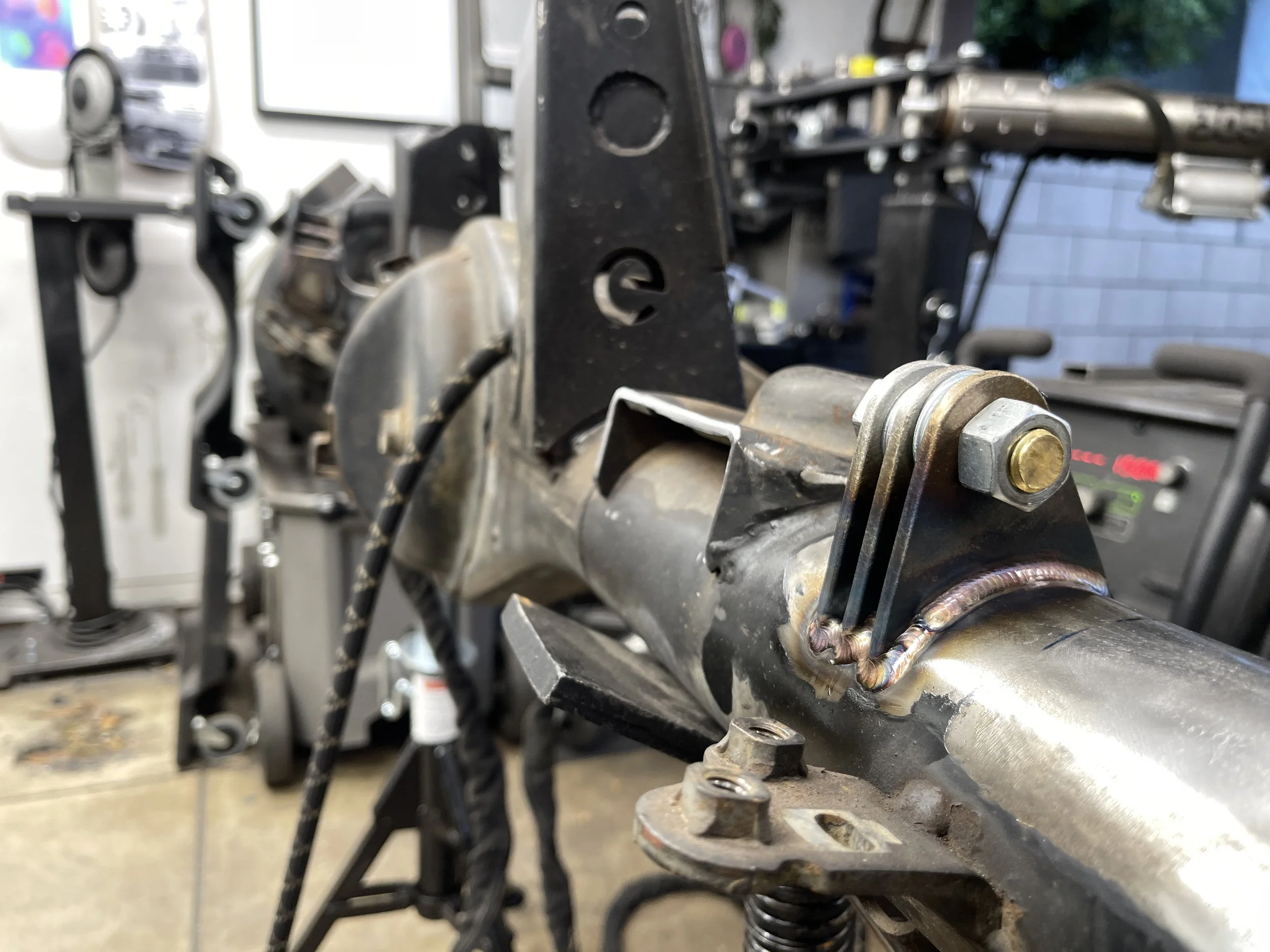

Fully welded out and double passed, the shock mounts proved to be quite a process. Given to me were plasma cut parts that had some modifications needed for final fitment. All in all, they cleaned up well and fit the part. Due to the kerfing and cutting process used for the skid plates, I opted to open the holes up and allow for 7/16 F911 bolts to mount up. Additionally, I again, opted to open up the shock bolt holes to allow for proper alignment. This in turn allowed me to burn in weld washers as well.

Once burned in, I was able to plate in the inner most are of the shock mount. This allowed me to fully ‘box-in’ the mount and allow for ample surface area to weld the shock hanger to the axle. Additionally boxing-in occurred from the lower link mount to the side of the shock mount.

A full prep and clean of the axle and add-ons was next on the list. I tried out POR15’s metal cleaner and prep and it proved to work as advertised. Interestingly enough, it etches the surface and nearly flash rusts within minutes. After a full wipe down is done, you’re ready to start applying paint.